Zhucheng Jinding Food Machinery Co., Ltd. was established in 1996, with its headquarters in Zhucheng, Shandong Province and a branch in Guangzhou.

The company is a professional operator integrating the design, research and development, manufacturing and marketing services of food sterilization equipment. It has formed an integrated enterprise integrating raw material supply, product development, process design, experimental design, finished product inspection, production, operation, storage and transportation, and technical services. An integrated and complete company operation system.

In recent years, the company has developed steadily. With the accumulation of old customers and the continuous addition of new customers, the turnover has increased year by year. At present, the company's products have passed multiple certifications and are sold to various countries, such as Malaysia, India, Philippines, South Korea, Vietnam, etc., and have obtained invention patents for a series of products and performance.

With strict quality control, 24-hour nanny-style after-sales service, and continuous innovation of new products, the company has created the trustworthy Jinding brand sterilization kettle, which has won favor in the market and high praise from peers.

As an industry leader and industry standard setter, Zhucheng Jinding Food Machinery Co., Ltd. has been focusing on food sterilization equipment to protect food safety, build a "firewall" for food safety, and protect "safety on the tip of the tongue." .

Water spray retort machine

1. Special heat exchanger for fully welded sterilization retort, with long life, high heat exchange efficiency, strong pressure bearing capacity and maintenance-free.

2. The nozzle adopts high-precision atomization nozzle, layered spray, full coverage of the product, no blind spots. With the excellent water circulation structure design, the temperature distribution is more uniform, the heat distribution is better than GB39948, and the optimal temperature difference can reach ±0.2℃.

3. The steam inlet is controlled by main and auxiliary valves, with high control accuracy and temperature control up to ±0.2°C.

4. The design and layout of the shortest distance water circulation pipeline reduces heat loss and pressure loss and reduces energy consumption.

5. The anti-whirlpool water tank design can effectively reduce the amount of circulating water, reduce water heat absorption, and reduce energy consumption.

(Projects 4 and 5 can save energy consumption by up to 15%)

The heat exchanger is used for indirect flexible cooling to ensure that there is no sudden rise or fall in pressure throughout the process, and the pressure control accuracy of the entire process can reach ±0.005MPa.

Water immersion sterilization retort machine

1. The optimized fluid dynamics water circulation design makes the temperature distribution more uniform, the heat distribution is better than GB39948, and the optimal temperature difference can reach ±0.2℃. Compared with the water flow switching mode used in the previous generation, the heat distribution effect is improved by 30%.

2. Use a large-flow circulating water pump to better improve heat transfer efficiency. The temperature control accuracy of ±0.2°C can be ensured through intelligent switch control of the steam main and auxiliary valves.

3. The top cooling water mode can make the sterilization intensity of the upper and lower products consistent and ensure the standardization of sterilization.

4. Reasonable pressure pipeline design, combined with the flexible use of Unicom pipelines and the addition of a soaking function after cooling water is supplied, ensure that the pressure control accuracy is ±0.005Mpa.

Steam air mixed sterilization retort machine

1. No water heat transfer, no need to exhaust steam, reducing energy consumption. Compared with other sterilization methods, energy consumption can be reduced by 30%.

2. Compared with steam sterilization, the pressure inside the sterilization retort is controllable and can be applied to more product types.

3. The fan current can be monitored in real time to ensure the standardized sterilization effect.

4. The optimized design of steam diffusion pipe and air duct plate can control the heat distribution effect to ±0.3℃.

5. The pressure is controlled in stages during cooling to effectively prevent product quality defects such as bulging, deflated, leaking, etc.

Rotary sterilization retort machine

1. The products are rotated 360° in the sterilization retort, which allows the products to be fully mixed and shaken during the sterilization process without stratification, thus preventing thermal damage to the surface products.

2. During the rotation process, the product flows within the package, which can also increase the heat penetration speed.

3. The three-point support form improves the stability of the equipment, better ensures the concentricity of the rotating structure, and improves the service life.

4. With brake device, it can realize fixed-point parking and ensure the levelness of the guide rail.

5. The compression device with more optimized positioning accuracy and structural strength ensures that the canned products will not shift during operation.

6. Updated tugboat design to improve the tugboat’s load-bearing capacity and service life.

7. The rotating body structure is designed through finite element simulation, with higher bending strength and torsion strength, and the overall structural safety factor is more than 2.

8. Reasonable pipeline design and circulating water pump selection, combined with precise program adjustment, can achieve temperature control accuracy of ±0.2°C and pressure control accuracy of ±0.005Mpa.

Laboratory sterilization retort machine

1. Complete functions, suitable for sterilization of all packages.

2. Small size and low energy consumption.

3. The equipment can add conditioning and sterilization (linear control), and can store 100 or more sterilization process formulas.

4. The equipment can add the function of real-time measurement of multi-point sterilization F0 value (heat penetration).

Flexible packaging automatic loading and unloading system

1. Instead of manually completing the tedious high-intensity work of loading, stacking, releasing, and unloading food before and after food sterilization.

2. The computer-controlled mechanical device completes the work of loading and unloading the discs, and the entire work process is completed automatically without manual intervention.

3. The loading and unloading methods are customized and suitable for non-destructive loading and unloading of most packaging products.

4. The computer controls the automatic transportation of the sterilizing tray and the automatic entry and exit of the sterilizing kettle.

5. Production quality and efficiency are controllable, not affected by workers' emotions, and quality standardization is achieved.

6. Automatic production reduces labor intensity of workers.

7. Reduce employment costs and reduce enterprise management costs.

8. The equipment operates 24 hours a day, creating greater profits for the company.

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

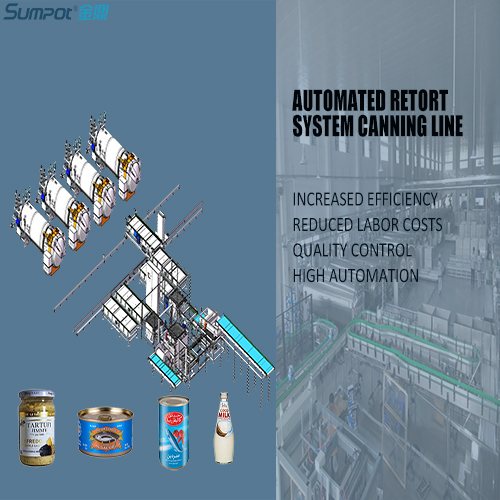

Automated Retort System Canning Line

Automated Retort System Canning Line

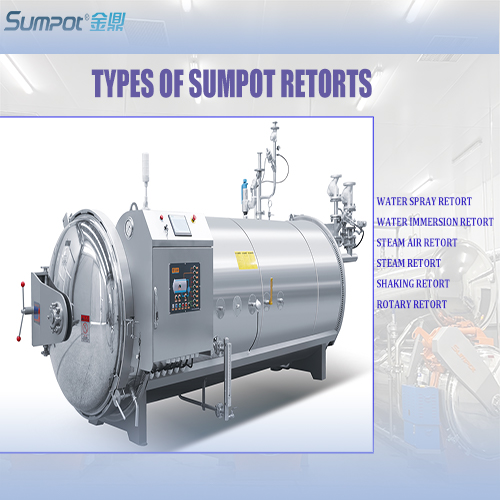

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT