Sterilization: Inject steam directly into the sterilization kettle. The steam in the retort is mixed with air through the fan and circulates continuously along the air duct of the equipment to evenly disperse the temperature in the sterilization retort. As the temperature continues to rise, the final control Within the set temperature range, effective sterilization is achieved.

Cooling: The cooling water enters the sterilization retort and circulates through the circulation pump to evenly cool down the sterilized objects. The cooling ends when it reaches the ideal temperature.

Drainage: Drain the remaining sterilization water through the drain valve, and drain all the pressure through the pressure relief valve.

1. Features

① Save energy. Compared with traditional steam sterilization retort, no exhaust is required, and steam is saved by about 1/4; Compared with water immersion and spraying, water is not used as an intermediate heat transfer medium, which saves steam consumption for heating water. ② There is no need for strict exhaust regulations, forced circulation by a fan, adjustable sterilization, and back pressure. ③The heating process is divided into several stages, and the speed of each stage is controllable, so one product can create a variety of flavors, and these procedures can be replicated industrially in each sterilization process.

2. Basic structure

The sterilizing retort is mainly composed of a cylinder part, a pneumatic part, a transmission part, an electric control part, etc. The cylinder body is welded from acid-resistant and heat-resistant austenitic stainless steel, and the pot door adopts a quick-opening form with reliable sealing and advanced structure; the pneumatic part includes pneumatic angle seat valves, pneumatic butterfly valves, cylinders, etc.; the transmission part includes reducers, tracks , water pumps, etc.; the electronic control part includes display screen, control box, control panel, temperature sensor, pressure sensor and other components.

3. Operation essentials and precautions

During the operation, attention should be paid to confirming the formula corresponding to the sterilization product before each operation to prevent product accidents caused by using the wrong formula; always pay attention to changes in water level during operation to avoid virtual water levels; during the insulation stage of the sterilization process, mercury thermometers, The temperature displayed by the temperature sensor and recorder is consistent and the switching status of each valve is correct; there should be no vibration or abnormal noise during use.

4. Routine maintenance and upkeep

1. Pressure gauge: With the pot door open, ensure that the pressure gauge pointer is within 1/2 of the minimum scale starting from 0.

2. Safety valve: ① Manually open the pressure valve, increase the equipment to 70% of the maximum working pressure, pull the safety valve stem to discharge dust. ② Confirm that the safety valve can open normally at the starting pressure value. If the safety valve does not work, or there is no reverse pressure relief, please adjust and repair it as soon as possible. If it cannot be repaired, replace it with a new one.

3. Filter: All filters on the equipment should be removed and cleaned once a month to avoid equipment abnormalities caused by filter blockage.

4. Air compressor: ① Check whether the belt of the air compressor is loose and replace it in time if the belt is aging. ② Check whether the air compressor is low on oil.

5. Pneumatic valves: Check each valve under pressure. If there is any leakage, it can be solved by tightening the bolts and replacing the seals.

6. Reducer: The bearings should be inspected, cleaned and greased regularly, with a six-month cycle.

7. When the equipment is out of service, the internal and external surfaces of the sterilization kettle and sterilization kettle cover should be cleaned.

keywords: retort machine, autoclave machine, food sterilization, retort processing, retort system, retort manufacturer, retort suppliers, food autoclave

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

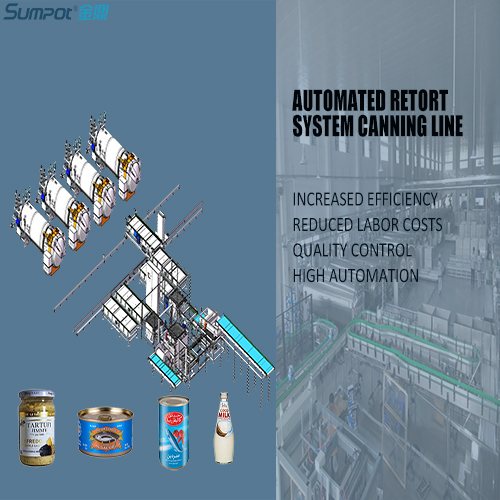

Automated Retort System Canning Line

Automated Retort System Canning Line

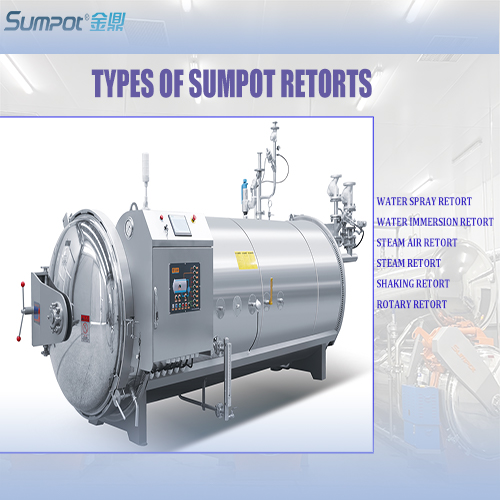

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT