The SUMPOT water spray retort machine is widely used in the food industry to sterilize food products such as beverage,meat, fish, vegetables etc. This type of food processing equipment is particularly useful for products that need to be preserved or processed in a hygienic and sterile environment.The working principle of water spray machine involves the following steps:

The SUMPOT water spray retort machine uses a closed system, which helps to maintain the desired temperature and ensure that the food product is heated evenly. This results in a more consistent and high-quality end product.

After the cooking process is complete, the temperature of the retort chamber is lowered, and the steam is condensed back into water, creating a dry, sterilized product. This dry and sterilized product can be used for various purposes, such as preservation, packaging, and further processing.

The machine is equipped with advanced technology and features, such as automatic control, precise temperature control, and automatic discharge, which ensures a consistent and reliable processing outcome. This helps to reduce the risk of contamination and ensure that the final product meets the required standards of quality and safety.

Overall, the SUMPOT water spray retort machine is an essential tool for the food industry, helping to improve food safety, hygiene, and quality, while also saving time and labor costs. With its advanced technology and reliability, this machine is well-suited for various food processing applications and is becoming increasingly popular among food manufacturers around the world.

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

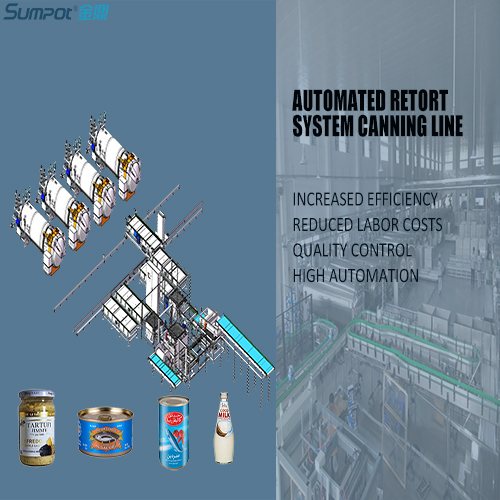

Automated Retort System Canning Line

Automated Retort System Canning Line

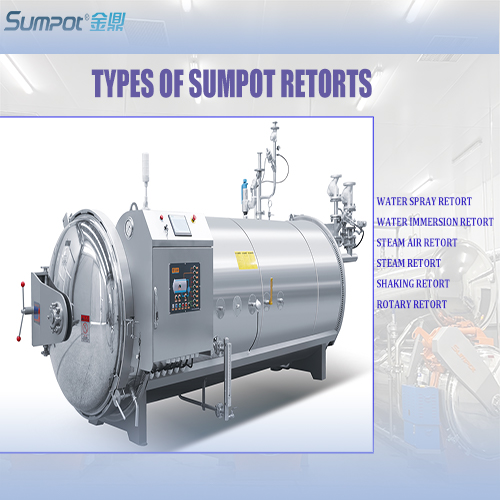

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT