Description

SUMPOT retort consists of a pot body, a lid, an opening device, a locking wedge, a safety interlocking device, a track, a sterilization basket, a steam nozzle and several nozzles. The pot lid is sealed with an inflatable silicone rubber temperature-resistant sealing ring, which has reliable sealing and long service life.

Using steam with a certain pressure as the heat source, it has the characteristics of large heating area, high thermal efficiency, uniform heating, short liquid boiling time, and easy control of the heating temperature. The inner pot (inner pot) of this pot is made of acid-resistant and heat-resistant austenitic stainless steel. It is equipped with a pressure gauge and a safety valve. It has a beautiful appearance, easy installation, convenient operation, safety and reliability.

Classification

There are four types of control methods:

1. Manual control type: All valves and water pumps are manually controlled, including water adding, heating, insulation, cooling and other processes.

2. Electrical semi-automatic control type: the pressure is controlled by an electric contact pressure gauge, the temperature is controlled by a sensor (pt100) and an imported temperature controller (accuracy is ±1°C), and the cooling process is manually operated.

3. Computer semi-automatic control type: Uses PLC and text display to process the collected pressure sensor signals and temperature signals. It can store the sterilization process, has high control accuracy, and the temperature control can reach ±0.3°C.

4. Computer fully automatic control type: All processes are controlled by PLC and touch screen, and the sterilization process can be stored. The operator only needs to press the start button. After the sterilization is completed, an automatic alarm will occur, and the temperature control accuracy can reach ±0.1°C.

There are three types of sterilization methods:

1. Hot water circulation sterilization: During sterilization, all the food in the pot is soaked in hot water. In this way, the heat distribution is relatively even.

2. Steam sterilization: After the food is put into the pot, water is not added first, but steam is directly added to heat it up. Since cold spots will appear in the air in the pot during the sterilization process, the heat distribution in this method is not the most uniform.

3. Water spray sterilization: This method uses nozzles or spray pipes to spray hot water onto the food. The sterilization process is through the nozzles installed on both sides or the top of the sterilization pot, spraying out mist-like waves. The hot water reaches the surface of the food, so it not only has a uniform temperature without dead spots, but also has rapid heating and cooling speeds. It can sterilize the products in the pot comprehensively, quickly and stably, and is especially suitable for the sterilization of soft-packaged foods.

Water spray sterilization can be divided into water spray rotary type; water spray static type; pulsating side spray water type, etc.SUMPOT is the top manufacturer of retort sterilization and production lines in China with 27 years of experience, there are different types of retort autoclave equuipment, which can be customized with different sizes and parameters, such as water spray retort, steam retort, water immersion retort, tuna precooking machine etc.

Generally, canned food factories use this form of horizontal sterilizing pot when boiling and sterilizing cans under normal pressure. This equipment can achieve back-pressure sterilization by introducing compressed air. If cooling needs to be carried out in the pot, a water pump must be driven into the water spray pipe on the top of the pot (or a water circulation system should be used).

During sterilization, as the temperature of the can increases due to heating, the pressure inside the can will exceed the pressure outside the can (in the pot). Therefore, in order to avoid the pressurization inside the glass bottle and jar during sterilization and the lid jumping, the two ends of the tinplate can are protruding, and counter pressure must be applied, especially for meat cans that require higher sterilization temperatures.

You are always welcome to ask for the best quotation to our professional sales manager, our retort machines have been exported to more than 90 countries in the past years, our products have been highly praised by our customers at home and abroad.

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

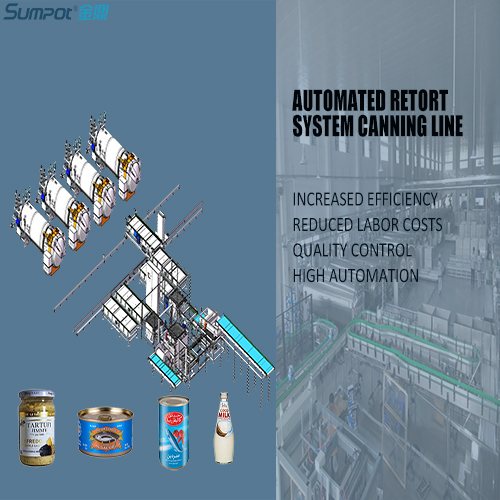

Automated Retort System Canning Line

Automated Retort System Canning Line

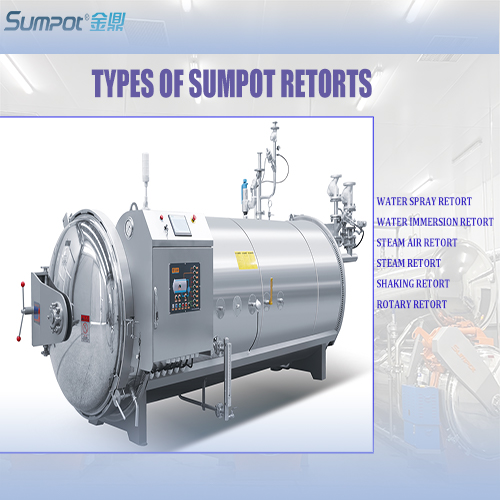

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT