The use of fully automated production lines in the food and beverage industry has had a significant impact on the production process. Automation has enabled the industry to produce large quantities of food and beverage products more efficiently, accurately, and at a lower cost. SUMPOT is aimed to help our customers to achieve the most of their production efficiency and business benefit with our advanced retort system processing lines, we have been developed multiple variety of processing lines such as canning line, pouch loading unloading line, which are totally full automatic operation system. Here are some of the outstanding benefits of usding fully automated production lines:

- Increased Efficiency: Automated production lines have significantly improved the efficiency of food and beverage production. They are designed to run continuously, which means that they can produce large quantities of products in a shorter period of time than manual production lines. SUMPOT canning line systems have been highly praised by our customers and peers domestic and overseas.

- Improved Accuracy: Automated production lines use advanced technology such as sensors, control systems, and software to monitor and regulate the production process. This results in higher levels of accuracy and consistency in the production of food and beverage products. SUMPOT automatic loading unloading line can reach a very high accuracy of processing food and beverage sterilization.

- Lower Cost: Automated production lines can produce food and beverage products at a lower cost than manual production lines. This is because the use of automated technology reduces the need for human labor and increases the efficiency of the production process. SUMPOT canning line can make the unmanned workshop automation possible, the production workshop can work continuously for 24 hours without manual intervention.

- Increased Product Quality: Automated production lines are designed to produce high-quality products consistently. They use advanced technology to ensure that each product meets the required standards of quality and safety.

- Faster Delivery: Automated production lines can produce large quantities of food and beverage products in a shorter period of time than manual production lines. This means that the products can be delivered to consumers faster, which is particularly important in the food and beverage industry.

Overall, the use of fully automated production lines in the food and beverage industry has had a significant impact on the production process, resulting in increased efficiency, improved accuracy, lower cost, increased product quality, and faster delivery.

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

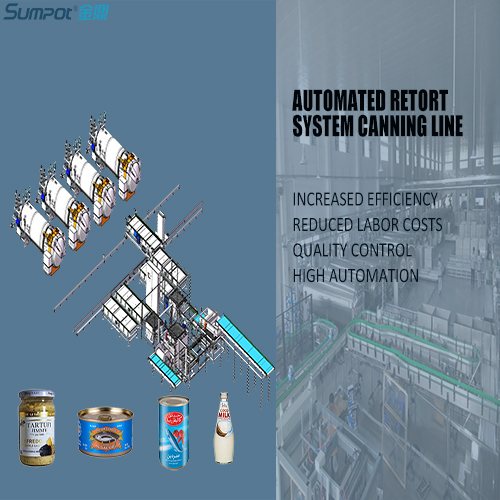

Automated Retort System Canning Line

Automated Retort System Canning Line

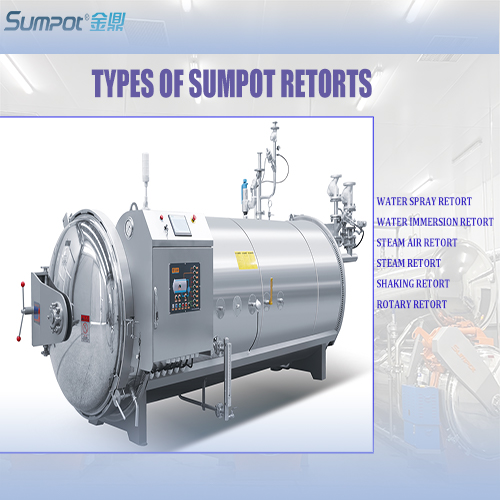

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT