The process of tuna fish sterilization, also known as canning or preserving tuna for long-term storage, typically involves the following steps:

Sorting and Cleaning: First, fresh tuna is carefully sorted, graded for quality, and cleaned to remove scales, fins, and internal organs. The fish is then washed thoroughly.

Pre-cooking: Tuna loins are often precooked by either steaming or boiling. This step helps to kill bacteria, reduce the moisture content, and make it easier to remove the bones.

Disassembling: The cooked tuna is then disassembled into smaller pieces or flakes, depending on the desired product (chunk, flake, or solid).

Sterilization: Canning is a form of sterilization itself. The tuna is placed in cans or jars along with any additional ingredients like water, oil, salt, or sauce. The containers are then sealed under vacuum or modified atmosphere conditions.

Heat Processing: The sealed cans undergo heat processing, which involves heating them at high temperatures (usually around 121-135°C or 250-275°F) in pressure cookers called retorts. This process ensures the destruction of all microorganisms that could cause spoilage or illness, effectively sterilizing the contents.

Cooling and Storage: After heat processing, the cans are rapidly cooled to room temperature and checked for seal integrity. Then, they are labeled and stored until ready for distribution.

It's important to note that while this process makes the canned tuna safe for consumption without refrigeration for several years, it does not render the fish incapable of reproducing; rather, the term 'sterilization' here refers to the elimination of harmful microorganisms, not the removal of reproductive capabilities.

Some types of tuna may also be treated with irradiation, a process that uses ionizing radiation to further sterilize and extend shelf life, but this is less common and subject to more stringent regulations.

Advantages of using tuna fish precookers:

Time-Saving: Tuna pre-cookers significantly reduce the cooking time as they precook the fish, making it ready for immediate use or further processing. This is especially beneficial in commercial kitchens or canning factories dealing with large quantities of tuna.

Consistent Quality: Pre-cooking ensures uniformity in the cooking process, guaranteeing that every piece of tuna is cooked to the right degree. It prevents undercooked or overcooked portions, maintaining the texture and flavor throughout.

Retains Nutrients: The controlled environment of a pre-cooker helps in minimizing nutrient loss that could occur from extended exposure to heat during traditional cooking methods.

Improved Food Safety: Pre-cookers can reach high temperatures necessary to eliminate potential pathogens, enhancing food safety by ensuring thorough cooking.

Cost-Effective: By streamlining the cooking process, pre-cookers can help save energy costs and increase productivity in a commercial setting, which in turn can lead to cost savings.

Easy Handling: Pre-cooked tuna is easier to handle for subsequent recipes like salads, sandwiches, or sushi, as it requires minimal additional preparation without the mess of raw fish.

Shelf Life Extension: Properly pre-cooked and canned tuna has an extended shelf life, making it suitable for storage and transportation without compromising its quality.

Versatility: Pre-cooked tuna can be used in a variety of dishes across different cuisines and is convenient for busy households or institutions where meal prep needs to be quick and efficient.

Enhanced Flavor: Pre-cooking can help infuse tuna with flavors during the cooking process, particularly if spices or marinades are used, resulting in more flavorful end products.

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

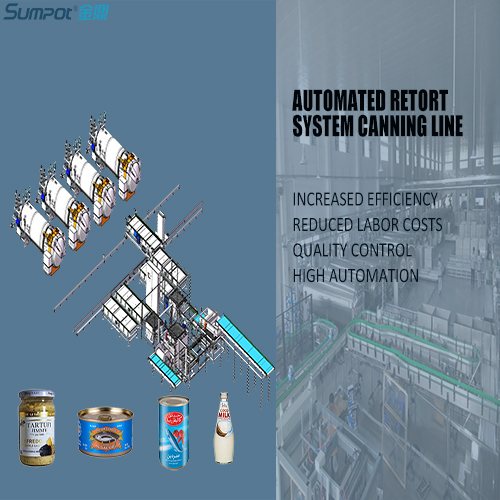

Automated Retort System Canning Line

Automated Retort System Canning Line

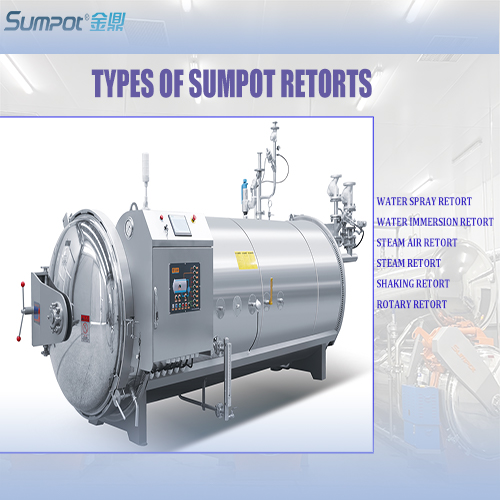

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT