Sterilization using retort autoclaves is a common practice in the food and pharmaceutical industries to eliminate bacteria, spores, and other pathogens from products. The temperature control requirements are stringent to ensure effective sterilization while not compromising product quality:

1. Initial Heating: The autoclave must rapidly heat the contents to achieve uniformity of temperature throughout the load. This typically involves a preheating stage where the temperature rises to around 80-90°C (176-194°F) for water-based products. This helps remove any cold spots and air from inside containers.

2. Sterilization Phase: The core temperature should reach and be maintained at the required F0 value (a measurement of sterilization intensity based on time and temperature) or equivalent parameters like saturated steam pressure for a specific holding time. For most low-acid foods, this is usually achieved by maintaining an internal temperature of about 121°C (250°F) under 15 psi (or above depending on altitude), and for sterilizing glassware or some pharmaceutical products, it can be up to 134°C (273°F).

3. Temperature Uniformity: It's crucial that all parts of the load, including the coldest spot, reach and maintain the sterilization temperature for the set duration. Autoclave loads should be arranged to promote even heat distribution, and the autoclave itself should have accurate temperature sensors to monitor this.

4. Cooling Phase: After sterilization, there needs to be a controlled cooling phase to prevent overprocessing or damaging heat-sensitive products. The temperature drop should be managed in such a way as to avoid creating condensation within the packaging which could reintroduce contamination.

5. Record Keeping: Temperature readings and time cycles need to be accurately recorded to provide evidence of proper sterilization and comply with regulatory standards.

keywords:retort machine,food sterilizer,industrial autoclave,sterilization equipment,retort processing in food industry,canning line,food production line,autoclave,retort sterilizer,retort system,horizontal retort

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

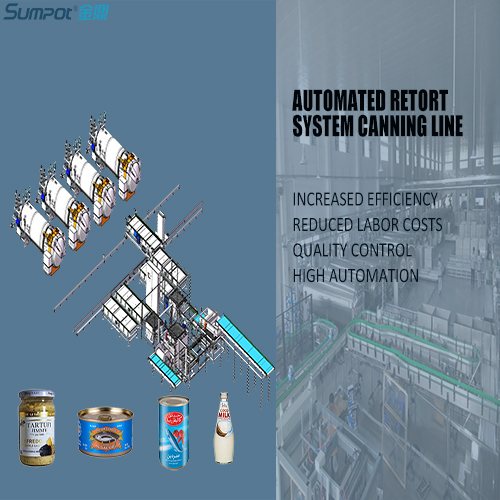

Automated Retort System Canning Line

Automated Retort System Canning Line

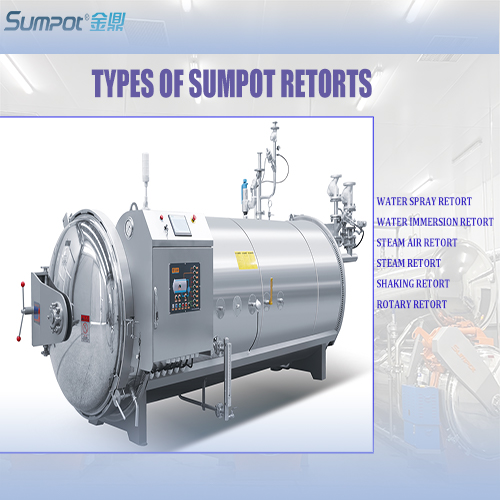

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT