Retort machines are becoming more and more important in the beverage industry nowdays, particularly in the processing and packaging of shelf-stable, aseptically filled beverages. You can find why from below points:

1. Sterilization: Retort machines process packaged beverages to high temperature for a specific period to eliminate pathogens (bacteria, viruses, spores), ensuring food safety. This process is known as retorting or sterilization, which can extend the product's shelf life no need under refrigeration condition. SUMPOT company is the top manufacturer for retort sterilization equipment in China for 28 years, we are not only the machine producers, but also we give the best sterilization solution for food and beverage industry.

2. Preservation of Quality: Although the process involves heating, our advanced retort technology has been designed to do under controlled conditions that minimize adverse effects on taste, color, appearance and nutritional value. The precise control over time-temperature profiles allows for effective pasteurization or sterilization while keeping the quality of the beverage intact.

3. Cost-effective Distribution: Beverages processed through retort machines can be distributed and stored without cold chains. This significantly reduces distribution costs and makes it possible to reach broader markets, including areas with limited refrigeration facilities.

4. Convenience and Portability: Retorted beverages come in easy-to-handle and ready-to-drink packages, which are ideal for on-the-go consumers and in situations where immediate consumption is preferred.

5. Extended Shelf Life: Retort processing provides beverages with an extended shelf life ranging from months to years, reducing waste due to spoilage and increasing the overall efficiency of the supply chain.

6. Great time saver: our retort machines are fully automatic operation, which can reduce the labor intensity, comparing to the traditionally manual operation retort in past years, our advanced retort technology has adopted the modern PLC control cabnit system, which is very easy to operate and maintain, and retorts adopt large flow pumps to cycle, which makes the whole sterilization working process more efficient and fast, the whole process can be controled precisely.

The use of retort machines in the beverage industry ensures food safety, preserves product quality, enables broder market reach, enhances convenience, and increases the longevity of beverages – all critical factors for a competitive and sustainable business. SUMPOT retort equipment has a long history of manufacturing food and beverage retort machinery with 28 year's experience, our equipment has been exporting to more than 100 countries, ou customers have already reached to 1000+, our goal in the 2024 is to serve our more advanced batch retort food production line to the whole world and let more customer to get the best of automation production. If you are interested to know more, you can always to get in touch with us.

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

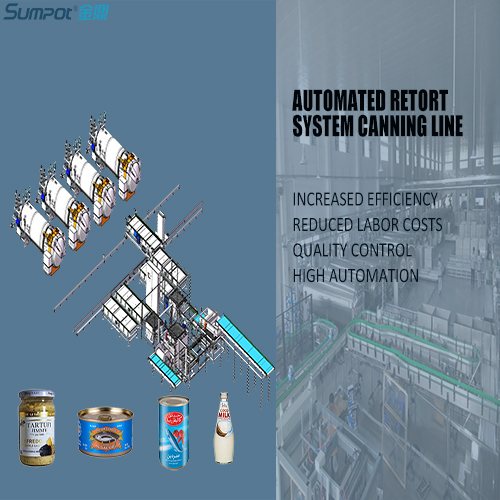

Automated Retort System Canning Line

Automated Retort System Canning Line

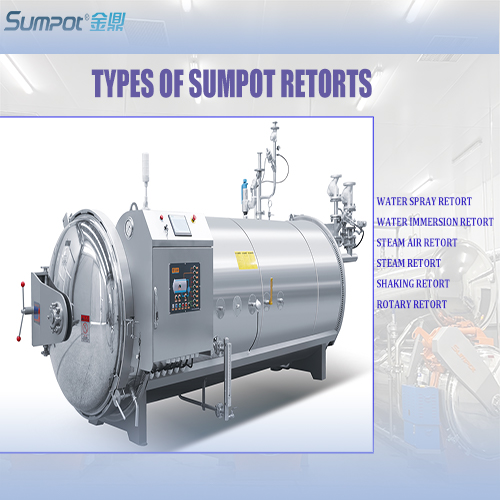

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT