SUMPOT is the top manufacturer for food and beverage retort sterilization equipment in China, with 28 years of experience we have extended the capabilities and technology for advanced batch retort systems, which are used in the food and beverage processing industry, to ensure their safety and extended shelf life. These systems are operational from handling soft bags, pouches, jars, cans, or trays to a high-speed loading/unloading system up to 1000-3,000 units per minute. You can take a look at the following advantages in an advanced batch retort system:

1.Precise Control:SUMPOT retorts come with advanced control systems that can precisely predict time, temperature, and pressure throughout the sterilization process. This matters the most because over-processing can decrease product quality when under-processing could lead to unsafe products condition. SUMPOT pays a lot attention on excellent control systems to ensure food quality and safety.

2.Automated Operation:SUMPOT company adopt the latest modern PLC control technology, to achieve the automatic operation, to adopt the optional control panel, also the real-time monitoring systems are becoming more efficient through the sterilization process.

3.Temperature Uniformity:SUMPOT focuses on advanced designs to ensure uniform heat distribution inside the retort chamber, to ensure all product containers receive the same thermal treatment, our retort equipment meets international standards and we have obtained the CE/ISO9001/ASME certification.

4. Data Logging and Traceability:Data logging capabilities record every aspect of the sterilization cycle, providing a detailed audit trail for quality control and regulatory compliance.

5. Energy Efficiency: SUMPOT retorts are designed to optimize energy efficiency through better insulation, faster heating rate, and more efficient cooling methods,save time and energy.

6. Adaptability: Our retorts can handle a wide range of packaging containers, including cans, pouches,trays, pp bottles, glass jars etc, allowing for flexibility in production lines.

7. Safety Ensurance: SUMPOT Overpressure and overheating protection mechanisms ensure operator safety and prevent damage in the sterilization process, safety level is our most first and formost goal in the production link, and we also have obtained the relevant safety administration authority certification.

Email us: [email protected] for more information on our advanced batch retort systems, visit www.sumpot.com for the full range of the company’s products and services.

SUMPOT Advanced Water Spray Retorts

SUMPOT Advanced Water Spray Retorts

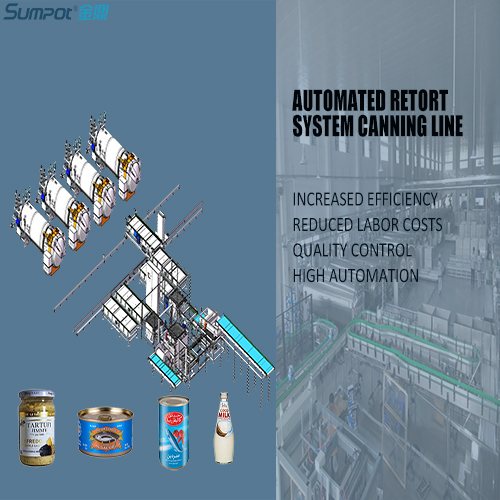

Automated Retort System Canning Line

Automated Retort System Canning Line

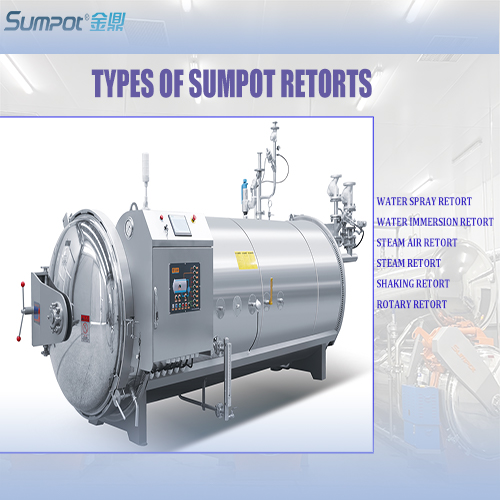

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT