Experimental pilot retort machine is designed for special sterilizing purpose developed by food and beverage processing enterprises in tests. It can be suitable for sterilizing a variety of packaging materials. It has water bath, water spray, air steam mixing, rotation, shaking, vibration etc different sterilization type. Generally it is a small or mini multifunctional sterilizing retort autoclave.

Polit retort machine is Suitable for Pe bottles, tin cans, soft pouches,gas-containing flexible packaging, glass bottles, and vacuum flexible packaging and any other food packages that are heating resistance.

Features of pilot multifunctional retort systems:

●Small size and low energy consumption.

●Full-featured, suitable for sterilization of all packages.

●Can measure multi-point sterilization F0 value (heat penetration) in real time.

●Can be adjusted and sterilized (linear control).

●Can store 100 or more sterilization process formulas.

Pilot retort working principle

Put the packaged products into the retort chambers, then close the retort door. The door ensures safety through triple safety interlocking,choose sterilization method,start the sterilization process, and the entire process will automatically follow the sterilization formula.

During the entire process, the pressure inside the sterilization retort is controlled by a program that sends or discharges compressed air into the sterilization retort through an automatic valve.

After sterilization is completed, the sterilization retort will send a signal, and the door can be opened and unloaded safely. The triple safety interlock ensures that the retort door will not be opened when there is pressure in the pot, thereby ensuring safe operation.

The temperature distribution uniformity in the sterilization retort is ±0.3°C, and the pressure is controlled at ±0.05Bar.

Features of pilot mini retort machines

Precise temperature controlled and uniform heat distribution

Sumpot Company independently developed a fully automatic linear control system that integrates heating, constant temperature, pressurization, cooling and other processes.

The system uses an advanced PLC system, a PID conditioning and sterilization system composed of temperature controllers and proportional control valves to control main parameters such as pressure and temperature in the kettle, monitor the temperature control and pressure curves during the sterilization process at any time, and track its Operating status, and monitor and adjust the working status of each valve during the sterilization process. By controlling the opening of the proportional regulating valve to keep the actual temperature and pressure consistent with the settings throughout the sterilization process, the temperature control accuracy can reach ±0.2 °.

Perfectly pressure controlling systems can ensure the pilot small retort machine can handle various packaging forms,such as tin cans,iron cans, aluminum cans, plastic bottles, soft pouches, plastic boxes, or flexible containers such as inflatable flexible packaging, it can be easily satisfied. The pressure can be controlled at ±0.05Bar.

High purity product packaging

While using the spray sterilization method in test ,the special heat exchanger for indirect heating and cooling, so that can avoid secondary contamination of packaged food ,the service life of the heat exchanger is also greatly extended, and it can also improve the quality of products and shelf life.

Comply with FDA certification

SUMPOT has experienced thermal verification experts, It fully cooperates with FDA-approved third-party thermal verification agencies. We have rich experience of cooperating with North American market, which makes SUMPOT familiar with FDA regulatory requirements and advanced sterilization technologies.

Energy saving and environmental protection

It adopts self-made high-quality plate and shell heat exchanger, which has compact structure, efficiency and saves energy,the rubber-free pad is more temperature-resistant and durable.

The pilot retort machine is designed as an invaluable tool for food and beverage sterilization development and research, and has also been instrumental in some start-ups trying to understand their own food recipes for further food production and development,commonly used in the development of new food products,comparing with regular size retort machines, pilot retorts is much more space-saved, time efficient, and energy saving to assess the impact of different processing conditions on product quality, safety, and shelf life.

In addition to product development and research, multifunctional mini retort machines also stand in the center in food process optimization and standardization. They enable manufacturers to regulate their processing protocols, assess the maximum efficacy of sterilization procedures.

Also pilot retort machines play an essential role for training purposes.Although it is not large in size and does not look that complicated, this machine will concentrate all the necessary functions into one, Through the operation of multi-functional retort, operators can easily acquire the necessary knowledge and skills for food sterilization, laying a solid foundation for subsequent more complex food sterilization processes in the future.

Above all,the experimental retort autoclave fully reflects its advantages in terms of energy saving, precise pressure control and perfect temperature regulation.Pilot retort machines are designed as an invaluable tool in the food industry, leading food companies into development and research for new products and food innovation.

For more information on our pilot mini retort machine, please click to inquiry as following:

https://www.sumpot.com/collections/multifunction-pilot-retort

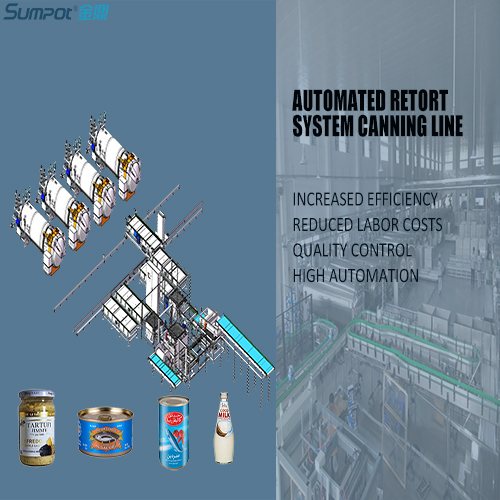

Automated Retort System Canning Line

Automated Retort System Canning Line

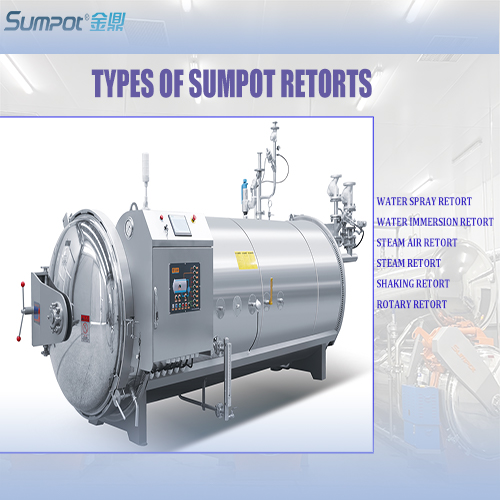

Types of Sterilization Retorts by SUMPOT

Types of Sterilization Retorts by SUMPOT

SUMPOT Water Immersion Retort Machine

SUMPOT Water Immersion Retort Machine