Sumpot water spray retort sterilizer is famous for its outstanding and consistent temperature distribution. It can achieve consistent product quality,

food safety, and extended shelf life.

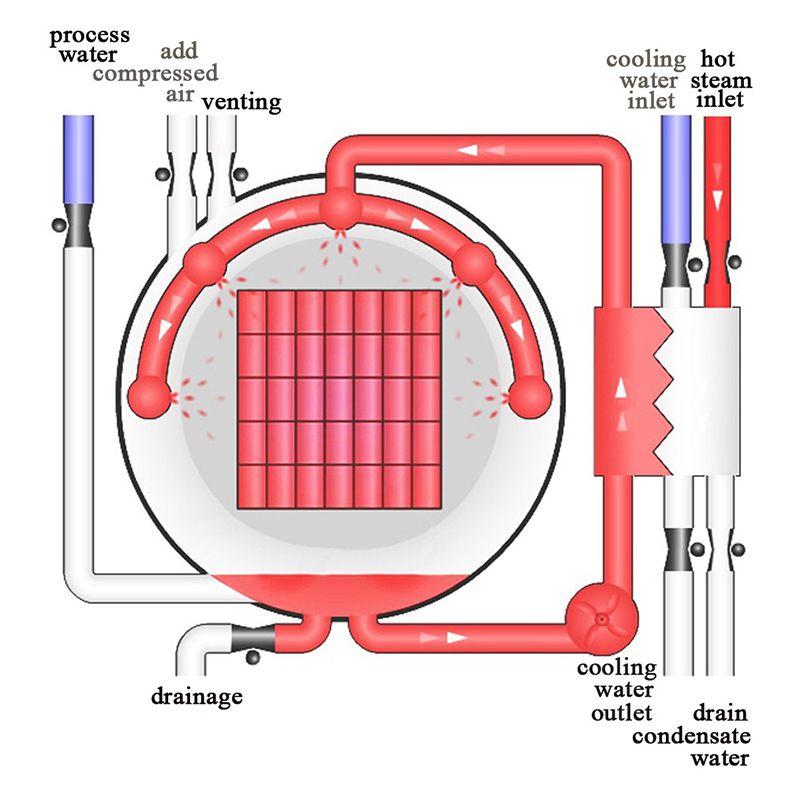

SUMPOT Water spray retort is equipped with a water spray device, heat exchanger, and powerful circulation pump.

Heating and holding phase: the powerful pump cycles the process water through retort and heat exchanger, the water is sprayed on the product surface,

shorten the cycle time .save energy, and makes heat distribution more uniform, all the products inside the retort get the same thermal treatment.

Cooling phase: the powerful pump cycles process water through retort and heat exchanger, all the products inside the retort are cooled the same,

regardless of their location.

Indirect heating and cooling can effectively avoid big temperature differences, process water for the cooling phase is sterilized during the heating

and holding phase, then it can effectively avoid secondary pollution. Help our customers to produce high-quality products with better flavor and appearance.

Application:

Meat products, fish products, vegetables, soups, ready-to-eat meals, protein beverages, pet food, baby food, and other foods are packed in flexible or rigid containers.

Advantages of using SUMPOT retort autoclave:

1. High heat capacity: SUMPOT retorts are designed to handle high temperatures, which allows for the efficient processing of a wide range of materials.

2. Rapid heating and cooling: SUMPOT retorts are capable of quickly heating and cooling materials, which makes them well-suited for a variety of industrial applications.

3. Flexibility: SUMPOT retorts can be adapted to process a wide range of materials, including solid and liquid materials, and can be configured in a variety of ways to suit different processes.

4. Energy efficiency: SUMPOT retorts are designed to be highly efficient, which can help to reduce energy costs and increase productivity.

Parameter:

keywords: retort,autoclave,food sterilization equipment,retort processing,retort machine,industrial autoclave,retort supplier,retort manufacturer,China retort factory