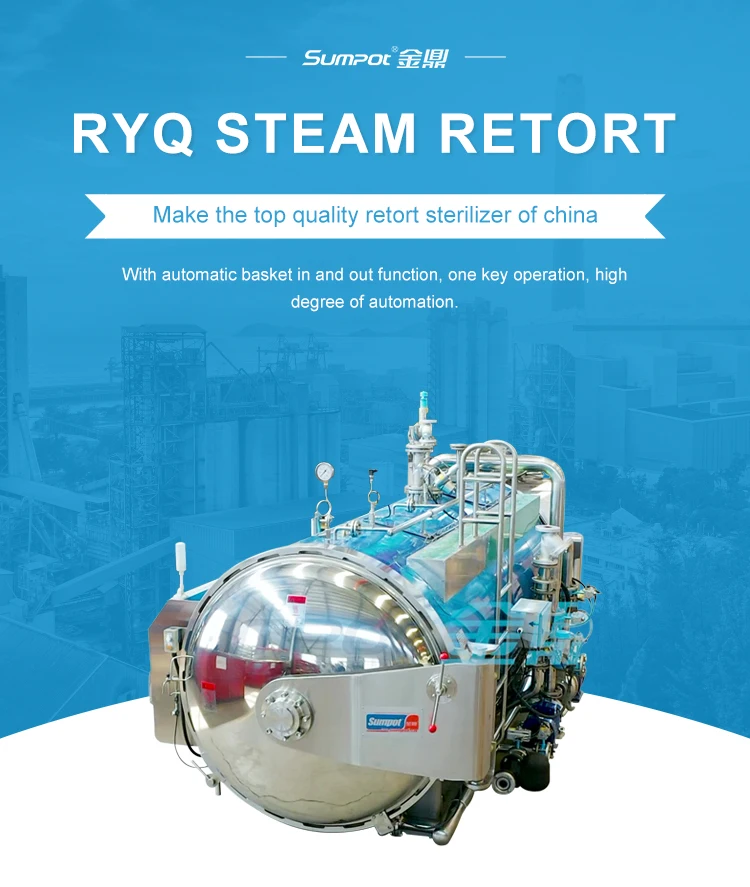

Description:

SUMPOT Steam Retorts are available for all types of products, saturated steam retorts are capable of immersion and spray cooling with overriding

pressure control as well as vacuum cooling, depending on your requirements. The steam retorts are designed for even temperature distribution to

deliver optimal come-up times. With the standard saturated steam retorts from SUMPOT, the steam retort is avaible with continuous support by our engineers.Optional flooded or heat exchanger cooling is also available. It sterilizes the food with injected hot steam directly.

Main Features:

1. The control of the whole sterilization process can be completed on the touch screen. The sterilization process requires such functions

as temperature, time, sterilization pressure, cooling pressure and cooling temperature to be customized. Can store germicidal process parameters

and improve production efficiency.

2. The whole process of heat preservation and cooling is controlled by PLC intelligently.All parameters are easy to input by PLC touch screen, and

can be stored in advance for many groups of bactericidal parameters.

3. High degree of automation.When the antiseptic basket of the product is pushed into the retort, the whole process of sterilization, temperature, sterilization, pressure, decompression and cooling are automatically completed by pressing the start button.

Applicable scope:

1. The heating and cooling speed is fast, and it can reach very high temperatures and pressures quickly, greatly shortening the sterilization time;

2. The maximum temperature is 135°C, and the sterilization effect is good. Under high temperature and high pressure, almost all germs can be killed;

3. Strong penetrating power, steam can penetrate thick breathable objects and kill spores;

4. Easy to operate, large-inch color touch screen, multi-language switchable, easy to operate after simple training;

5. Save time, and use time more effectively through functions such as scheduled start and preheating functions;

6. Various programs. In addition to setting each sterilization program, you can also set any project for repeated operations;

7. Shorten the take-out time, and the cooling fan is equipped as standard. After the sterilization is completed, the cooling fan will operate to quickly cool down to a safe temperature;

8. High safety, with safety lock settings, over-temperature and over-pressure protection devices, and water and power outage protection functions;

9. Computer control, no need for human supervision, saving human resources and other advantages.